Developing pathways to large scale Direct Air Capture.

For over a decade, Carbon Engineering has advanced technologies for capturing carbon dioxide (CO2) from the air around us.

How It Works

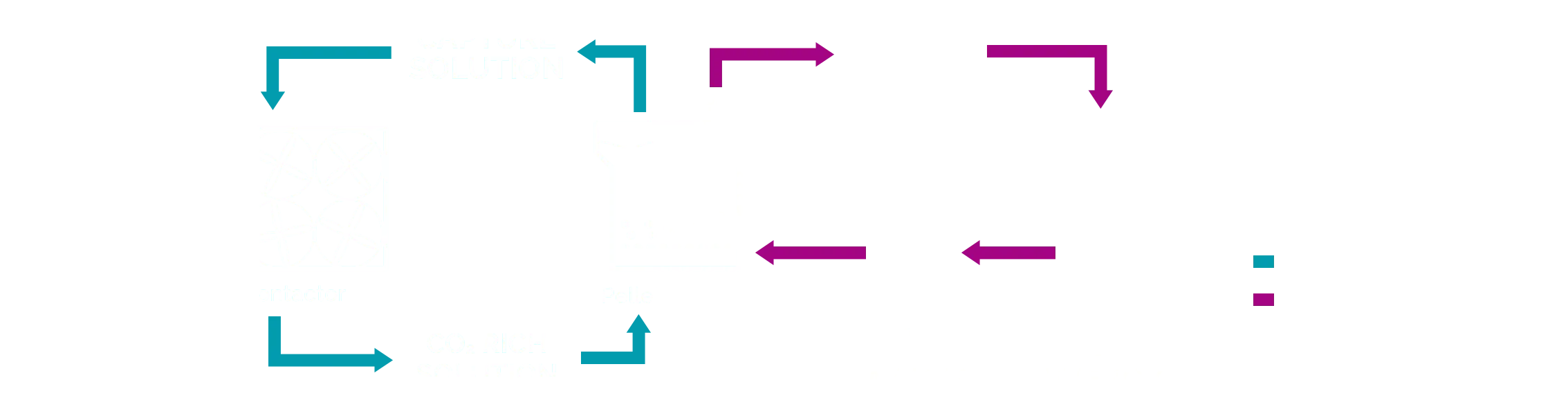

Capture

Fans move air into a contactor unit–modeled off industrial cooling towers–where it meets a liquid sorbent running across a PVC structure. This structure increases the surface area inside the unit enabling greater air-to-sorbent contact efficiency.

Regeneration

After capture, the CO2-rich sorbent enters the regeneration phase of the Direct Air Capture process–which concentrates and purifies the captured carbon dioxide. Here, we take advantage of centralization rather than modularity, allowing us to process larger volumes of CO2.

The chemical processes used in both the capture and regeneration steps operate in parallel as a closed-loop system, meaning we can minimize input-driven waste and costs.

Benefits

Closed Loop Operation

Carbon Engineering's liquid-based approach to Direct Air Capture uses closed-loop chemistry in a continuous operation–meaning we can reuse materials in the process to minimize cost and waste.

Modular Where It Matters

The capture system is built in modular trains, taking advantage of all the benefits of mass manufacturing, while regeneration equipment is large to take advantage of volumetric scaling laws.

Scalable Standard Design

Using equipment with industrial precedent and existing supply chains in a "design one, build many" approach allows for the near duplication of plants adjusted for location-specific considerations.

Transparent and Verifiable

The output of Carbon Engineering's process is a near pure stream of atmospheric CO2 that can be easily measured using common equipment, like flow meters, according to existing standards.

Stratos

First of its kind.

The first commercial facility to use Carbon Engineering's technology is well underway in the United States. Designed to capture up to 500,000 tonnes of carbon dioxide annually once fully operational, it is expected to be the largest in the world.

Learn more about STRATOSUse Cases for Captured Carbon Dioxide

When paired with secure geologic storage, Direct Air Capture provides a measurable and scalable CO2 removal (CDR) pathway. Climate experts, including those from the Intergovernmental Panel on Climate Change, agree that alongside accelerated and widespread emissions reductions, billions of tonnes of carbon dioxide (CO2) will need to be removed. Today, industry leaders–from Airbus to Amazon and beyond–have purchased CDR credits from 1PointFive, using Carbon Engineering's technology, to help reach their net-zero goals.

DAC also provides a nearly infinite feedstock of CO2 from the atmosphere that can be recycled and used to produce low-carbon intensity products, such as fuels and other materials like plastics or concrete. CO2 utilization supports a circular emissions reduction pathway.

Contact 1PointFive to Learn More